The Technology of Building Houses Using a 3D Printer: How it Works

In recent years, the volume of residential construction worldwide has been increasing. At the same time, however, housing costs have been rising as well. In the United States, for example, the median price of a new home grew from about $330,000 in 2020 to more than $410,000 in 2024.

Under these conditions, it is hardly surprising that governments, developers, and private builders are actively searching for alternative methods of constructing houses that are faster, less labor-intensive, and potentially more affordable.

One such alternative approach is construction using 3D printing. This refers to large-scale machines that layer by layer deposit construction mixtures, forming the walls of a building directly on site. At the same time, like any new phenomenon, house printing has its own specific features and limitations.

In this material, we examine in detail what exactly 3D-printed housing construction entails, how this technology emerged, and what prospects it has.

What is 3D House Printing

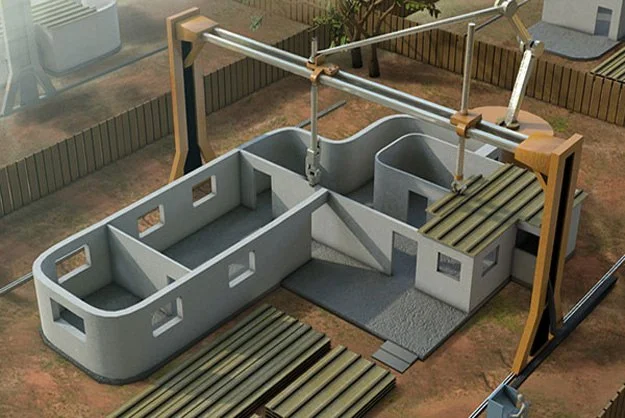

In construction, 3D printing means forming structural elements using large robotic installations. The machine applies a building mixture layer by layer according to a pre-prepared digital model, gradually creating the geometry of the walls.

In the vast majority of completed projects, builders do not print the entire house. Instead, they primarily print load-bearing and enclosing walls, partitions, and elements of the building envelope. Foundations, floors, roofs, windows, doors, and engineering systems are almost always built using traditional construction methods.

The first attempts to print building elements date back to the early 2010s. At that time, projects mainly consisted of demonstration pavilions, small architectural forms, and experimental walls.

A turning point occurred in the second half of the 2010s, when three factors coincided:

- New construction mixtures appeared that could be easily extruded while still retaining their shape after deposition.

- The construction industry began to experience a growing shortage of skilled labor, which pushed companies to look for ways to automate work processes.

- There was an increasing need to reduce production costs. Developers started seeking methods that would use less material and speed up the construction process.

This combination of factors led to the development of new technology and equipment. By 2014–2015, it had already become possible to build the first fully 3D-printed house. A robotic system that moves a printing head along a predetermined trajectory while continuously supplying the mixture became the basic design of the printer. Over time, three main technical variations emerged from this model:

- Portal systems, in which the printing head moves along rails within a fixed frame structure.

- Crane-based solutions, where the printing head is suspended from a boom or travels along tracks around the construction site.

- Industrial robotic arms adapted from traditional manufacturing robotics.

Two main technological approaches have been established:

- The first approach involves printing directly at the construction site. In this case, nothing needs to be transported in prefabricated form, since the house is built on location. However, this requires careful consideration of weather conditions and the logistics of delivering materials to the site.

- The second approach involves printing large structural elements in a factory and then assembling them at the construction site. The main drawback of this method is the need to transport oversized components.

How Houses are Printed on a 3D Printer

The approach of assembling ready-made elements on site is straightforward, so we will focus on how house printing works when the printer is located directly at the construction site.

First, engineers convert the architectural project into a digital model. Based on this model, they define the movement trajectories of the nozzle, the height and width of each layer, the speed of material extrusion, as well as the locations of openings and technological channels.

Before printing begins, basic utility connections are installed at the site, after which the printer itself is set up. Specialists conduct a test print, and if everything functions properly, they launch the main printing program. In a number of projects, walls are not printed as solid structures but with internal cavities that are later filled with insulation material.

Once the wall printing is completed, builders install floors and roofing, mount windows and doors, lay engineering systems, and carry out finishing works. In dome-shaped projects, the roof is most often printed as well.

The Current State of the 3D Construction Industry

Today, 3D printing in construction is considered a promising field. This is reflected in market assessments. For example, Grand View Research estimates the global market for 3D printing in construction at approximately $53.9 million, with projected growth to $4.18 billion by 2030. Mordor Intelligence provides more optimistic figures, forecasting about $2.46 billion in 2025 and $11.8 billion by 2030.

In Europe, a multi-apartment building was erected using 3D printing in 72 hours of actual printing time, followed by roughly six additional weeks of traditional construction work. At the end of 2025, the German construction company PERI and the Danish 3D printer manufacturer COBOD presented serial 3D-printed housing projects.

They also stated that such projects are built 30 percent faster and about 10 percent cheaper compared to similar properties constructed using conventional methods. In the United States, entire neighborhoods of 3D-printed homes are already emerging, and at the same time the technology is being used in resort and premium real estate projects.

Nevertheless, this approach still faces a number of challenges:

- Limited scope of application. At present, printers are mainly used to create only the basic structural frame of a house. Before printing, builders must construct the foundation, and after printing they still need to install all engineering systems, the roof, windows, doors, and other elements.

- Regulatory restrictions. Houses built with 3D printers are difficult to evaluate under existing building standards. Countries still need to develop specific regulations for such structures.

- Material and structural issues. The strength of bonding between printed layers remains a subject of debate. Experts note that after hardening, materials may shrink, which can lead to cracks.

- Difficulties with reinforcement. Reinforcing concrete with steel bars is a fundamental principle of modern construction. When using 3D printing, incorporating reinforcement into walls is technically complex, which means that constructing high-rise buildings with this method would be as costly as traditional construction.

Notable Projects Using 3D Printing

There are now a number of projects in which 3D printing is highlighted as a key marketing element. The United States leads in adapting the technology, where such projects have already reached a commercial stage, although examples also exist in other countries.

- Wolf Ranch, Georgetown, Texas, USA. From the start of construction in November 2022 until its completion in August 2024, the project delivered 100 3D-printed houses.

- Mehrfamilienhaus Wallenhausen, Bavaria, Germany. This is a three-storey multi-apartment building with a total area of 380 square meters and only five apartments.

- Zuri Gardens, Houston, USA. A project comprising 80 middle-class homes that received support from state authorities under the Affordable Home Development Program.

- TECLA, Massa Lombarda, Italy. TECLA is a house printed from local clay, designed with an emphasis on biodegradability and a closed material cycle.

The average price of a house in Wolf Ranch ranges from $450,000 to $600,000, which is roughly $100,000 cheaper than conventional equivalents. Zuri Gardens offers even more affordable prices, ranging from $270,000 to $350,000. It is difficult to compare the German and Italian projects directly, since they are largely one-off buildings and their exact costs are not publicly disclosed.

Future Outlook for 3D-Printed Construction

The most likely growth area over the next five to ten years is serial low-rise and mid-rise housing. Another niche where the technology could take root faster than in the general housing market is infrastructure and auxiliary buildings.

However, even with rapid market expansion, 3D printing is unlikely to become a universal replacement for traditional construction. Most buildings will remain hybrid, since printing mainly covers the structural frame while the rest of the work continues to rely on conventional methods.

At the same time, there is a high probability that adoption will proceed more slowly than many expect. Bureaucracy in individual countries, particularly in Europe, tends to be rigid, and standards for 3D-printed buildings will likely be developed gradually. This challenge will be compounded by the need to create international standards that all countries can follow.

Frequently Asked Questions

What are 3D-printed houses made of?

3D-printed houses are usually built from special construction mixtures based on concrete. These materials are designed to be sufficiently fluid during extrusion, to set quickly, and to form stable walls without the need for traditional formwork.

How much does a 3D-printed house cost?

In North America, the average cost of 3D-printed housing ranges from $100 to $150 per square foot, which corresponds approximately to $1070–$1610 per square meter, excluding interior finishing and installation of engineering systems. More optimistic estimates place the cost in the range of $860–$1610 per square meter.

How fast are houses printed?

Printing the wall structure can take from several days to several weeks. In Ireland, for example, 3D printing the walls of two-storey houses required only 12 days.

In some U.S. projects, wall printing work can take about four to six weeks, whereas constructing a comparable house using traditional wood framing or brickwork usually requires six to eight months.

Is it safe to live in a 3D-printed house?

Houses with printed walls have demonstrated good resistance to climatic stresses. Prototypes in Texas, particularly in Wolf Ranch in Georgetown, have shown resilience to hurricanes, tornadoes, and fires, while also providing effective thermal insulation. Manufacturers generally aim to use non-toxic materials in construction mixtures.

However, during the curing process, the material may shrink, which can lead to shifts in structural loads and, as a result, the formation of cracks.

Author

I write informative articles about real estate, investments, job opportunities, taxes, etc.